The research and teaching activity profile of the Laboratory of Composites and Polymer Materials Research includes carrying out tests in the scope of the evaluation of mechanical, rheological, chemical and functional properties of plastics and polymer composites, including polymer biocomposites with fillers of natural origin. In the scope of the assessment of rheological properties, the performed tests concern, among others, assessment of the viscosity of plastics with the use of a capillary rheometer, as well as the assessment of utilitarian parameters in the form of flow rates of polymeric materials with the use of a plastometer. The equipment for testing mechanical properties allows to perform uniaxial tensile tests, assess the hardness of plastics, as well as determine the impact tensile strength. Chemical properties are determined with the use of a spectrometer that allows to generate the spectrum of the tested materials, in addition, a scanning calorimeter is used for thermal tests to determine the heat flux in relation to the temperature of the tested materials. For the accelerated evaluation of the durability of polymeric materials, an aging test chamber is used to reflect the actual atmospheric conditions affecting the test sample. In addition, to assess the properties of composite structures in the context of, inter alia, the quality of the surface layer of the sample, the orientation of the filler fibers, etc., an optical and workshop microscope are used.

LABORATORY EQUIPMENT

Instron Ceast Smart RHeo 2000 Capillary Rheometer

Plastic viscosity testing. Testing the flow of thermoplastics for shear rates up to 5000 s-1. Determining the pVT diagram for plastics.

FTIR ThermoFisher Nicolet iS10 Spectrometer

Testing the infrared radiation spectrum of polymeric and composite materials. Identification of newly formed chemical compounds by identifying individual functional groups.

Q-SUN Xe-1-S Xenon Test Chamber

Testing the influence of atmospheric factors: light, increased temperature, rain on the surface of materials.

Q-2000 Differential Scanning Calorimeter

The device enables measurement of the transformation temperature and the heat flow associated with the phase transformation in the sample. As a result of the analysis, a thermogram is obtained that shows the heat flow per unit time depending on the temperature. DSC is widely used in the design, selection, comparison and quality control of synthetically produced polymers, proteins and other macromolecular compounds. Properties measured with TA Instruments DSC include glass transition temperature, melting, crystallization, oxidation stability, and curing kinetics of polymers.

Instron Ceast Melt Flow Tester

Determination of melt flow rates of polymeric materials, i.e. mass melt flow rate (MFR) and volumetric melt flow rate (MVR).

Zwick 3106 Hardness Tester

Plastic hardness tests in accordance with PN-EN ISO 2039-1.

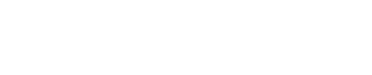

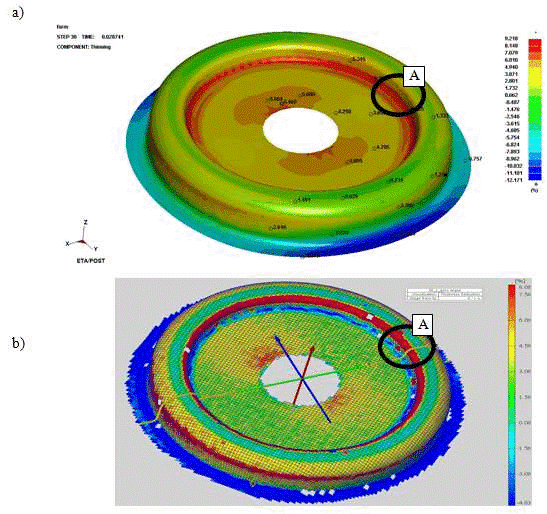

Deformation analysis device with software – ARGUS system

The ARGUS forming analysis system supports the optimization of the sheet metal forming process, taking into account the correct material selection and tool optimization. The system allows to detect critical areas of deformation, solve complex molding problems, optimize molding processes, verify tools, and verify and optimize numerical simulations.

CEAST 9050 Impact Pendulum

Impact tensile strength tests of plastics in accordance with PN-EN ISO 8256

Nikon LV100 Polarizing Microscope

Polarizing microscope for advanced research. The microscope works in transmitted and reflected polarized light.

Nikon MM-800 Measuring Microscope

The microscope is designed for industrial measurement and image analysis. The device has a built-in table position reading system.